microbialcellfactories.biomedcentral.com

Scaling up the production of fungal perylenequinones and investigating their biosynthesis through stable isotope labeling - Microbial Cell Factories

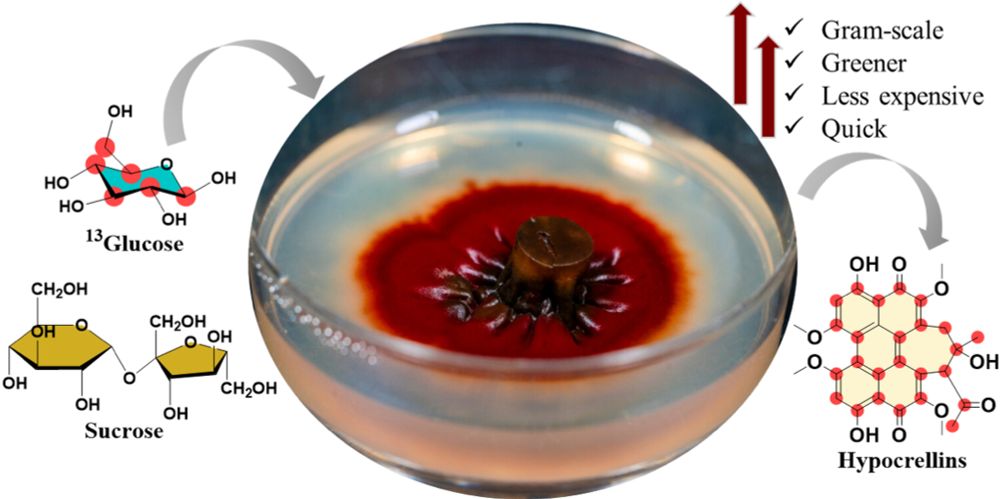

Background Perylenequinones, such as hypocrellins and hypomycins, are fungal secondary metabolites with potential for pharmaceutical and industrial applications due to both their physical and biological properties. This study focused on their sustainable production. Additionally, stable isotope labeling was used to probe the biosynthesis of these compounds, demonstrating how sugars are likely incorporated into the perylenequinone scaffold. Methods Shiraia sp. (strain MSX60519; Shiraiaceae, Pleosporales) was cultivated under varying nutrient conditions to evaluate the production of perylenequinones, with sugars serving as primary carbon sources. Five metabolites were isolated (from oatmeal cultures) using environmentally friendly solvent-based techniques, and the process was further optimized to maximize yields. High-performance liquid chromatography (HPLC) and liquid chromatography–high-resolution mass spectrometry (LC–HRMS) were employed to detect, characterize, and quantify the major compounds. Furthermore, feeding experiments were performed using 13C-labeled glucose, with droplet probe mass spectrometry used to monitor stable isotope incorporation in situ. Results This study yielded three key findings. First, the production of perylenequinones was significantly enhanced by supplementing fermentation media with sugars, and disaccharides significantly enhanced the production of perylenequinones compared to monosaccharides. Optimizing sugar concentrations during the fermentation further influenced the profile of secondary metabolites. Second, stable isotope labeling experiments confirmed that sugars are the primary building blocks of perylenequinones, as noted by tracing 13C-labeling into ent-shiraiachrome A (1). Finally, a green, scalable, and sustainable strategy for producing these compounds on the gram scale was developed by optimizing fermentation conditions, refining purification methods, and improving extraction efficiency. Conclusion These findings provide critical insights into optimizing fermentation conditions for the scaled and sustainable production of perylenequinones. This approach offers a cost-effective and environmentally friendly pipeline for harnessing these valuable compounds, paving the way for broader pharmaceutical and industrial applications. Graphical abstract

T. Keith Edmunds

T. Keith Edmunds